Measurements of Crane Runways, Profiles and Fastenings

GLM Lasermesstechnik has developed a system for measuring crane runways. The evaluation is based on the standards ISO 12488-1 and VDI 3576 for the new construction, reconstruction and repair of crane runways. The results of the crane runway survey are automatically output a few minutes later by using the software package (3-DIM Crane). 3-DIM Crane consists of a Microsoft Excel® based application and a plug-in for Rhino3D® or 3-DIM PC-Basic. The measurement is performed by a 3D measuring system with 3-DIM Observer Motorized

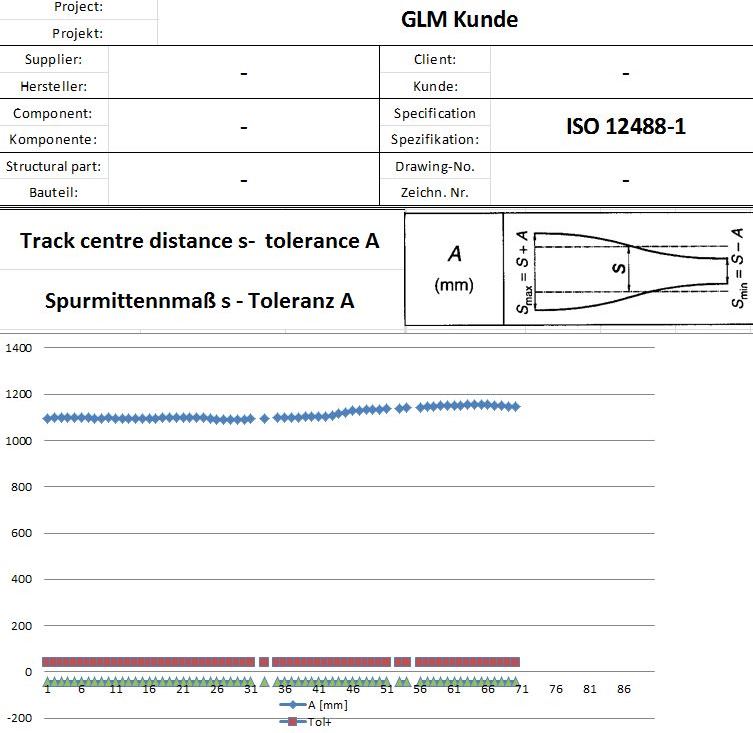

The automated test protocol provides information about:

- Tolerance of span „s“ – tolerance A

- Tolerance of horizontal straightness of rail head – tolerance B

- Tolerance of straightness related to the height of crane rail center – tolerance C

- Tolerance of height related to opposite track – tolerance E

- Tolerance of parallelism of end stops – tolerance F

- Tolerance of inclination difference of opposite rails – tolerance N

Components of the measuring system are a motorized industrial tachymeter (laser station), a field computer or tablet and a rail measuring carriage equipped with spherical adapter. Among other things, the 3D measuring system is characterized by:

- Measuring accuracy up to:

- longitudinal position +/- 0,2 mm

- Cross position and height +/- 0.05 m

- One-man operation, mobile and easy to use

- Measuring head automatically tracks the spherical adapter

- Immediate correction values if necessary for adjusting the rail or track

- Resistant to difficult environmental conditions (high IP)

- Minimal impairment of operational processe

- Measurement in loaded and unloaded operation possible

Thanks to the visual graphics, first results can be discussed on site